-

JoroI have got the machines and the sliding table saw are really good quality.

JoroI have got the machines and the sliding table saw are really good quality.

Heating Processing Electric Lifting Woodworking Sliding Panel Saw

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Scoring Saw Power | 1.1kw | After-sales Service Provided | Engineers Available To Service Machinery Overseas,video Technical Support, Online Support,field Maintenance And Repair Service |

|---|---|---|---|

| Voltage | 220v/380v/415v/440v Or As Customer Request | Style | Horizontal |

| Main Motor Power | 5.5kw | Dimension(l*w*h) | 3400*1200*1200mm |

| Highlight | sliding carriage panel saw,felder panel saw |

||

Horizontal High Precision Woodworking Sliding Panel Saw MJ6132S

Factory supply Top Quality Woodworking Sliding Panel Saw With Electric Digital Readout Mj6132s

Precision Sliding Table Saw Machine with Electric Lifting and Digital Readout For Furniture & Cutting wood MJ6132S

Inner Structure

This machine uses linear guideway to lift the saw blade which is more smooth and more durable. Aluminum shell motor makes sure its good heat dissipation. 25mm metal plate guarantees the compressive strength and the high precision of the inter-machine, which can also reduce the shock of the machine.

![]()

![]()

![]()

2.Main Saw and Scoring Saw Spindle

After the heating processing and dynamic balancing treatment, our saw spindle will never deformation. With high quality belt and motor, our machine has lower noise, higher precision and higher efficiency of power transmission.

![]()

![]()

3.SKF Bearing of Sliding panel saw

All bearings in the wood working machine are all imported SKF brand, which has lower sliding resistance and power consumption comparing with ordinary bearings.

![]()

4.Sliding Table Structure and Feature

Our sliding table supplier is the same as SCM. Our table is made of fully-extruded, anodized aluminum that will stay square and true over many years of use. The guideway of movable table is steel bar structure. After quenching and chromizing, our table is more smooth and less resistance. The comb lock on the table makes it convenient to stop anywhere.

![]()

![]()

5.Cast-iron Main Table and Broaden Extension Table

(sliding panel saw )

After precision casting and flat grinder treatment, our cast-iron table greatly reduces the friction between the workpiece and the table, which makes sure of the cutting accuracy. Broaden extension table makes the operation more convenient.![]()

![]()

6.Supporting Arm and Cross Cut Table

Our support arm uses 2.5mm square steel tube, which insure the stationary movement of sliding table when the machine has heavy loading.

![]()

![]()

7.Movable Positioning Stops and Cross Cut Fence

The positioning stops are made of high quality aluminum alloy with extrusion and precision processing, which is very durability. There are two types for your choice.

![]()

![]()

8.Altendour-structure Dust Cover

This device can make sure better dust collection effect, which is suitable for main saw blade diameter 400mm and maximum cutting height 120mm. It’s position is flexible, and it’s very safe for the operator.

![]()

![]()

9.Controlling Board

main saw blade and scoring saw blade are both electric control which makes it easy to operate. The angle tilting adjustment is also electric lifting with digital readout.

![]()

10.Rip Fence Fine Adjustment

Fine adjustment range is between 0-10mm, which makes the saw cutting size more precise. It is also very easily to adjust with digital readout.

![]()

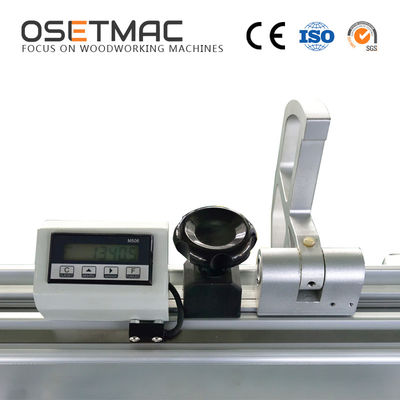

11.Digital Readout

![]()

![]()

![]()

12.Saw Blade Guard and Hand Swage

![]()

![]()

More Trading Details

| Model | MJ6132S |

| Payment Terms | T/T |

| Delivery Time | Negotiable (7-30DAYS) |

| FOB Port | Qingdao Port, China |

| Country of Origin | China |

| HS CODE | 8465910000 |

| Certificate | CE ISO |

Our Certificate :

We have CE and ISO certificate ,Think All our models can meet the quality level in your market .

![]()

Different outlook for different customer

![]()

Our Warehouse

![]()

![]()

![]()

![]()

![]()

Applications:

This machine apply to processing all kinds of density boards, shaving boards, wood-based panels, ABS panels, PVC panels, organic glass plates and solid wood and others with wood structure and similar hardness.

Specifications:

|

Packing and Loading container

![]()

![]()

![]()

![]()